SDY355 BUTT FUSION Welding Machine

Bayani na Musamman

Kafin sarrafa na'ura, kowa ya kamata ya karanta wannan bayanin a hankali kuma ya kiyaye shi da kyau don tabbatar da amincin kayan aiki da ma'aikacin, da amincin sauran.

2.1 Ana amfani da na'ura don walda bututu da aka yi daga PE, PP, PVDF kuma ba za a iya amfani da su don walda kayan ba tare da bayanin ba, in ba haka ba na'urar na iya lalacewa ko kuma haifar da wani haɗari.

2.2 Kada a yi amfani da injin a wurin da ke da haɗarin fashewa

2.3 Ya kamata a yi amfani da na'ura ta hanyar alhaki, ƙwararrun ma'aikata da horarwa.

2.4 Ya kamata a yi amfani da injin akan busasshen wuri. Ya kamata a ɗauki matakan kariya lokacin da ake amfani da shi a cikin ruwan sama ko a ƙasa mai jika.

2.5 Ana sarrafa injin ta 220V± 10%, 50 Hz. Idan ya kamata a yi amfani da tsawaita waya, yakamata ya sami isasshen sashin gubar gwargwadon tsayinsa.

2.6 Kafin amfani da injin, cika 46 # mai na ruwa. Tabbatar cewa man hydraulic ya isa don aiki; matakin mai ya kamata ya zama 2/3 na tanki. Sauya hular tankin mai na baƙin ƙarfe ta jajayen filastar iska mai zubar jini ko matsa lamba ba za a iya riƙe ba.

Tsaro

3.1 Kula lokacin aiki da jigilar injin bisa ga duk ƙa'idodin aminci a cikin wannan umarnin.

3.1.1 Sanarwa lokacin amfani

l Ma'aikacin ya zama mai alhaki da horar da ma'aikata.

l Cikakken dubawa da kula da injin a kowace shekara don aminci da amincin injin.

l Wurin aiki mai ƙazanta da ƙuri'a ba zai rage ingancin aiki kawai ba, amma yana haifar da haɗari cikin sauƙi, don haka yana da mahimmanci a kiyaye tsaftar wurin aiki kuma babu wasu cikas.

3.1.2 Power

Akwatin rarraba wutar lantarki yakamata ya kasance yana da mai katsewa a ƙasa tare da ma'aunin amincin wutar lantarki mai dacewa. Ana nuna duk na'urorin kariyar aminci ta kalmomi ko alamomi masu sauƙin fahimta.

Ƙarƙashin ƙasa: Duk rukunin yanar gizon yakamata ya raba waya ɗaya na ƙasa kuma tsarin haɗin ƙasa yakamata a kammala kuma a gwada shi ta hanyar kwararru.

3.1.3 Haɗin injin zuwa wuta

Na'urar haɗin kebul zuwa wuta yakamata ta zama jujjuyawar inji da hujjar lalata sinadarai. Idan aka yi amfani da tsayin waya, dole ne ya sami isasshen sashin gubar gwargwadon tsayinsa.

3.1.4 Adana kayan lantarki

Don min. Haɗari, dole ne a yi amfani da duk kayan aiki kuma a adana su daidai kamar haka:

※A guji amfani da waya ta wucin gadi ba ta bi ka'ida ba

※ Kar a taɓa sassan electrophorus

※ Hana cire kebul don cire haɗin

※ Hana jigilar igiyoyi don ɗaukar kayan aiki

※ Kar a sanya abu mai nauyi ko kaifi akan igiyoyin, kuma sarrafa zafin kebul a cikin iyakacin zafin jiki (70℃)

※ Kada ku yi aiki a cikin yanayin jika. Bincika idan tsagi da takalma sun bushe.

※ Kar a fantsama injin

3.1.5 Bincika yanayin rufin injin lokaci-lokaci

※ Duba insulation na igiyoyi musamman maki extruded

※ Kar a yi aiki da injin a cikin matsanancin yanayi.

※ Bincika idan canjin yatsa yana aiki da kyau aƙalla kowane mako.

※ Duba ƙasa na injin ta ƙwararrun ma'aikata

3.1.6 Tsaftace kuma duba injin a hankali

※Kada a yi amfani da kayan (kamar abrasive, da sauran abubuwan kaushi) suna lalata rufin cikin sauƙi lokacin tsaftace injin.

※ Tabbatar cewa an kashe wutar lantarki lokacin kammala aikin.

※ Tabbatar cewa babu wani lalacewa a cikin injin kafin sake amfani da shi.

Idan kawai bin abin da aka ambata a sama, yin taka tsantsan zai iya aiki da kyau.

3.1.7 farawa

Tabbatar cewa an rufe mashin ɗin kafin kunna ta.

3.1.8 Ba a yarda mutumin da ba shi da horo ya yi aiki da injin kowane lokaci.

3.2.Hatsari masu yuwuwa

3.3.1 Butt fusion Machine sarrafawa ta hanyar na'ura mai aiki da karfin ruwa:

Kwararren mutum ne kawai ke sarrafa wannan injin ko wasu masu takardar shedar aiki, in ba haka ba hatsarin da ba'a so zai iya haifar da shi.

3.3.2 Farantin dumama

Max zafin jiki na iya isa 270 ℃, don haka ya kamata a lura da wadannan abubuwa:

----Saba safofin hannu masu aminci

-------Kada ku taɓa saman farantin dumama

3.3.3 Kayan aikin tsarawa

Kafin aske bututun, yakamata a tsaftace ƙarshen bututun, musamman tsaftace yashi ko sauran daftarin da aka yi a kusa da iyakar. Ta hanyar yin wannan, za a iya tsawaita rayuwar ɗan adam, da kuma hana askewa a jefar da mutane masu haɗari.

3.3.4 Tsarin Mahimmanci:

Tabbatar an gyara bututu ko kayan aiki daidai don samun daidaitaccen jeri. Lokacin haɗa bututu, mai aiki ya kamata ya ajiye wani wuri zuwa na'ura don amincin ma'aikata.

Kafin jigilar kaya, tabbatar da cewa an gyara duk ƙugiya da kyau kuma ba za su iya faɗuwa yayin sufuri ba.

Bi duk alamun aminci a cikin injin.

Bayani

Injin ya ƙunshi firam na asali, naúrar ruwa, farantin dumama, kayan aiki da tallafi.

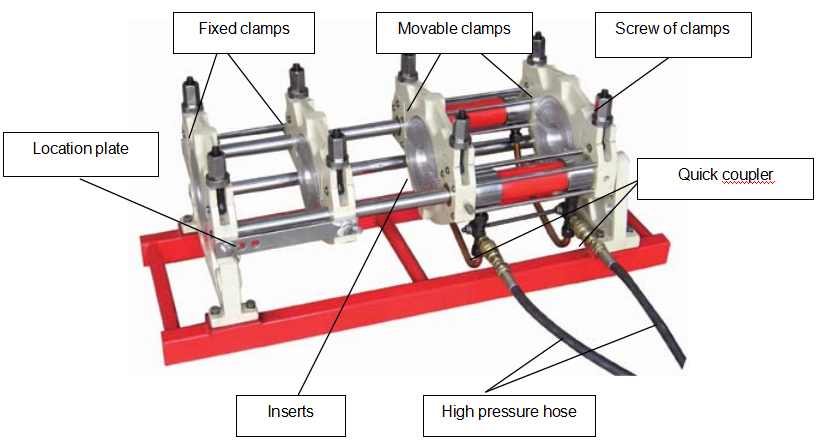

5.1 Frame

5.2 Kayan aiki na tsarawa da farantin dumama

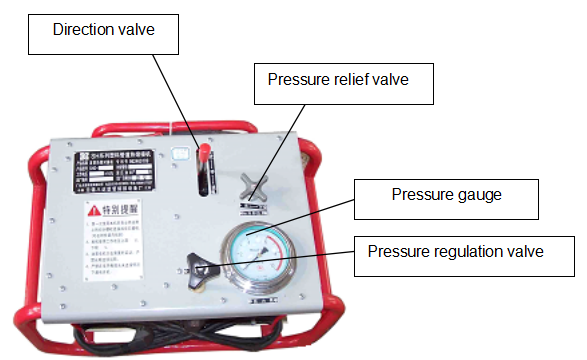

5.3 Na'urar Ruwa

Umarnin don Amfani

6.1 Ya kamata a sanya dukkan kayan aiki a kan jirgin sama mai tsayi da bushe don aiki.

6.2 Kafin aiki tabbatar da abubuwa masu zuwa:

u Injin yana cikin yanayi mai kyau

u Wutar ta cika da buƙatun bisa ga injin fusion ɗin butt

u Layin wuta bai karye ko sawa ba

u Duk kayan aikin al'ada ne

u Wuraren kayan aikin tsarawa suna da kaifi

u Duk sassan da ake buƙata da kayan aikin suna samuwa

6.3 Haɗi da shirye-shirye

6.3.1 Haɗa ainihin firam zuwa naúrar ruwa ta ma'aurata masu sauri.

6.3.2 Haɗa layin farantin dumama zuwa akwatin lantarki a cikin naúrar hydraulic.

6.3.3 Haɗa layin farantin dumama zuwa farantin dumama.

6.3.4 Shigar da abubuwan da suka dace don tsarawa bisa ga diamita na waje na bututu / kayan aiki.

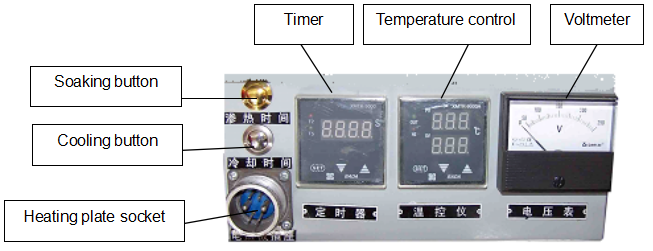

6.3.5 Dangane da bukatun dacewa da tsarin walda, saita zafin jiki a cikin mai sarrafa zafin jiki kuma saita lokaci a cikin mai ƙidayar lokaci. (Dubi sashe na 7 wannan littafin.)

6.4 Matakan walda

6.4.1 Bututu

Kafin waldawa, da farko, bincika idan kayan da matsinsa sune ake buƙata. Na biyu a duba idan akwai tsage-tsafe ko fissure a saman bututu/ kayan aiki. Idan zurfin ɓarna ko fissure ya wuce kashi 10% na kaurin bango, yanke ɓangaren ɓarna ko fissures. Tsaftace saman ƙarshen bututu da kyalle mai tsafta don kiyaye ƙarshen bututun mai tsabta.

6.4.2 Matsala

Sanya bututu / kayan aiki a cikin abubuwan da aka saka na firam kuma kiyaye iyakar da za a walda su zama tsayi iri ɗaya (babu tasiri akan tsari da dumama bututu). Ya kamata a goyan bayan bututun daga cikin firam na asali zuwa tsakiyar axial na clamps. A ɗaure skru na ƙugiya don gyara bututu / kayan aiki.

6.4.3 Daidaita matsa lamba

Buɗe bawul ɗin ƙa'idar matsa lamba gaba ɗaya, kulle bawul ɗin rajistan juyawa sosai sannan tura gaba bawul ɗin shugabanci yayin da yake daidaita bawul ɗin ƙa'idar matsa lamba har sai silinda ya fara motsawa, a wannan lokacin matsa lamba a cikin tsarin shine matsa lamba.

Buɗe bawul ɗin ƙa'idar matsa lamba gaba ɗaya, kulle bawul ɗin rajistan juyawa da ƙarfi sannan tura gaba bawul ɗin shugabanci yayin da yake daidaita bawul ɗin ƙa'idar matsa lamba don saita matsin tsarin daidai yake da matsa lamba yana ƙara matsa lamba.

6.4.4 Tsara

Buɗe ƙarshen bututu / kayan aiki bayan kunna bawul ɗin rajistan juyawa gaba da agogo zuwa ƙarshen. Sanya kayan aikin tsarawa tsakanin ƙarshen bututu / kayan aiki kuma kunna shi, rufe bututu / kayan aiki ta ƙare ta aiki akan bawul ɗin shugabanci yayin da sannu a hankali kunna bawul ɗin duba agogon agogo har sai an sami ci gaba da aski da ke bayyana a bangarorin biyu. Juya bawul ɗin juyawa zuwa agogon agogo don rage matsa lamba, cikin ɗan lokaci kaɗan buɗe firam ɗin, kashe kayan aikin shirin sannan cire shi.

Rufe bututu/madaidaicin iyakar kuma duba daidaitawar su. Matsakaicin madaidaicin madaidaicin kada ya wuce kashi 10% na kauri na bango, kuma ana iya inganta shi ta sassautawa ko ɗaure skru na manne. Rata tsakanin iyakar bututu guda biyu kada ta wuce 10% na kauri na bango; in ba haka ba ya kamata a sake shirya bututu / kayan aiki.

Tsanaki: Kauri na shavings yakamata ya kasance tsakanin 0.2 ~ 0.5 mm kuma ana iya daidaita shi ta hanyar daidaita tsayin igiyoyin kayan aiki na tsarawa.

6.4.5 Dumama

Share ƙura ko tsaga a saman farantin dumama (Tsaki: Kada a lalata Layer PTFE akan saman farantin dumama.), Kuma tabbatar da zafin jiki ya kai wanda ake bukata.

Saka farantin dumama tsakanin ƙarshen bututu bayan ya kai yawan zafin jiki da ake buƙata. Rufe ƙarshen bututu/ kayan aiki ta hanyar bawul ɗin shugabanci kuma ɗaga matsa lamba zuwa ƙayyadadden matsa lamba ta hanyar jujjuya bawul ɗin ƙa'idar matsa lamba har sai dutsen ya kai tsayin daka.

Juya bawul ɗin dubawa gaba da agogo baya don rage matsa lamba (ba fiye da ja da matsa lamba ba) kuma kunna bawul ɗin rajistan jujjuyawar agogon agogo zuwa ƙarshen.

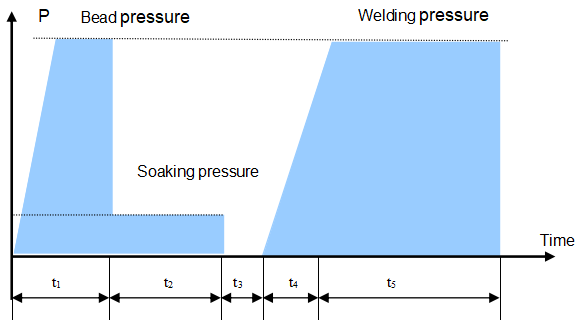

Danna maɓallin "T2” , lokacin jiƙa ya fara ƙirgawa kuma lokacin zai ƙidaya zuwa sifili da biyu, sannan buzzer zai yi buzz (duba sashe na 7)

6.4.6 Haɗuwa da sanyaya

Bude firam ɗin kuma fitar da farantin dumama kuma rufe ƙarshen narkewa biyu da sauri.

Ci gaba da bawul ɗin bawul ɗin jagora a kusa da wurin kusa don 2 ~ 3 mintuna, sanya sandar bawul ɗin shugabanci a matsakaici kuma danna maɓallin ("T5") don ƙidaya lokacin sanyaya har sai ya ƙare. A wannan lokacin, injin zai sake ba da ƙararrawa. Sauke matsa lamba, kwance dunƙule na dunƙule sannan a fitar da bututun da aka haɗa.

Mai ƙididdige ƙididdigewa da Mai Kula da Zazzabi

Idan an canza ɗaya daga cikin sigogi, kamar diamita na waje, SDR ko kayan bututu, lokacin jiƙa da lokacin sanyaya yakamata a sake saita su bisa ga ma'aunin walda.

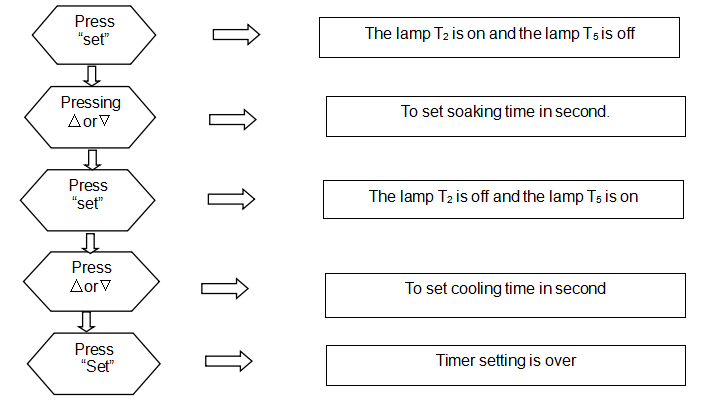

7.1 Saitin lokaci

7.2 Umarnin don Amfani

7.3 Saitin mai sarrafa zafin jiki

1) Danna "SET" na tsawon fiye da 3 seconds har sai an nuna "sd" a cikin babban taga

2) Latsa "∧" ko "∨" don canza ƙimar zuwa ƙayyadaddun (latsa "∧" ko "∨" ci gaba, ƙimar za ta ƙara ko rage ta atomatik)

3) Bayan saitin, danna "SET" don komawa zuwa sa ido da sarrafawa

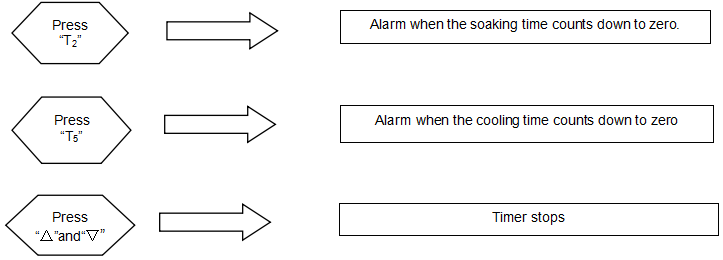

Bayanin Matsayin Welding (DVS2207-1-1995)

8.1 Saboda bambanci a cikin daidaitattun walda da kayan PE, lokaci da matsa lamba sun bambanta a matakai daban-daban na waldi. Yana ba da shawarar cewa ainihin sigogin walda ya kamata a ba da su ta bututu da masana'antun kayan aiki.

8.2 Ba waldi zafin jiki na bututu sanya daga PE, PP da PVDF da DVS misali jeri daga 180 ℃ zuwa 270 ℃. Aikace-aikacen zafin jiki na farantin dumama yana cikin 180 ℃ 230 ℃, kuma max. surface zafin jiki iya isa 270 ℃.

8.3 Ma'aunin Magana DVS2207-1-1995

| Kaurin bango (mm) da | Tsayin bead (mm) | Ƙunƙarar Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙwara | Lokacin jiƙa t2( dakika) | matsa lamba (MPa) | Canje-canje a lokaci guda t3( dakika) | Lokacin gina matsi t4( dakika) | Welding matsa lamba (MPa) | Lokacin sanyi t5(min) |

| 0 zuwa 4.5 | 0.5 | 0.15 | 45 | ≤0.02 | 5 | 5 | 0.15 ± 0.01 | 6 |

| 4.5 zuwa 7 | 1.0 | 0.15 | 45 zuwa 70 | ≤0.02 | 5 zuwa 6 | 5 zuwa 6 | 0.15 ± 0.01 | 6 zuwa 10 |

| 7 zuwa 12 | 1.5 | 0.15 | 70 ~ 120 | ≤0.02 | 6 zuwa 8 | 6 zuwa 8 | 0.15 ± 0.01 | 10 zuwa 16 |

| 12 zuwa 19 | 2.0 | 0.15 | 120 ~ 190 | ≤0.02 | 8 zuwa 10 | 8 zuwa 11 | 0.15 ± 0.01 | 16 zuwa 24 |

| 19 zuwa 26 | 2.5 | 0.15 | 190 zuwa 260 | ≤0.02 | 10 zuwa 12 | 11 zuwa 14 | 0.15 ± 0.01 | 24 zuwa 32 |

| 26 zuwa 37 | 3.0 | 0.15 | 260 ~ 370 | ≤0.02 | 12 zuwa 16 | 14 zuwa 19 | 0.15 ± 0.01 | 32 zuwa 45 |

| 37 zuwa 50 | 3.5 | 0.15 | 370 ~ 500 | ≤0.02 | 16 zuwa 20 | 19 zuwa 25 | 0.15 ± 0.01 | 45 zuwa 60 |

| 50 ~ 70 | 4.0 | 0.15 | 500 ~ 700 | ≤0.02 | 20 zuwa 25 | 25 zuwa 35 | 0.15 ± 0.01 | 60 zuwa 80 |

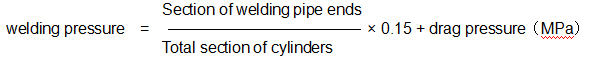

Lura: Matsi na ginawa na bead da matsin walda a cikin nau'i shine matsin lamba da aka ba da shawarar, yakamata a lissafta ma'aunin ma'auni tare da dabara mai zuwa.

Magana:

Binciken Malfunctions da Magani

8.1 Matsalolin ingancin haɗin gwiwa akai-akai suna nazari:

8.2 Lokacin kulawa da dubawa

8.2.1 Kulawa

※ Rufe farantin wuta

Da fatan za a kula da sarrafa farantin dumama. Tsaya tazara nesa da farantin dumama. Dole ne a yi tsabtace saman sa tare da dumi har yanzu ta amfani da zane mai laushi ko takarda, guje wa abubuwan da za su iya lalata rufin.

A lokaci-lokaci duba kamar haka

1) Tsaftace saman ta hanyar amfani da kayan wanke-wanke mai sauri (giya)

2) Duba tightening na sukurori da na USB da kuma toshe yanayin

3) Tabbatar da yanayin zafinta ta amfani da infrared-ray scanning

※ Kayan aikin tsarawa

Ana ba da shawara mai ƙarfi don kiyaye kullun kullun tare da wanke tarkace ta amfani da abin sabulu. A lokaci-lokaci na yau da kullun, aiwatar da cikakken aikin tsaftacewa.

※ Naúrar Ruwa

A kiyaye shi kamar haka

1) Bincika matakin mai lokaci-lokaci

2) Sauya mai gaba ɗaya kowane wata 6

3) Tsaftace tanki da kewayen mai

8.2.2 Kulawa & Dubawa

Dubawa na yau da kullun

| Abu | Bayani | Duba kafin amfani | Na farko wata | Duk wata 6 | Kowanne shekara |

| Kayan aikin tsarawa | Niƙa ko maye gurbin ruwa Sauya kebul ɗin idan ya karye Sake ƙarfafa haɗin injiniyoyi |

● ● |

● |

| ● ●

|

| Farantin dumama | Sake haɗa kebul da soket Tsaftace saman farantin dumama, sake gyara Layer PTFE idan ya cancanta Sake ƙarfafa haɗin injiniyoyi | ● ●

● |

● |

|

●

|

| Temp. tsarin sarrafawa | Duba ma'aunin zafin jiki Sauya kebul ɗin idan ya karye |

● |

|

| ● ● |

| Tsarin ruwa | Duba ma'aunin matsi Sauya hatimi idan na'urar ruwa ta zube Tsaftace tace Tabbatar cewa man ya isa aiki Canza man hydraulic Sauya idan bututun mai ya karye |

● ● ● |

|

● | ● ●

● ●

|

| Na asali Frame | Maimaita sukurori a ƙarshen axis na firam A sake fesa fentin antirust idan ya cancanta | ●

| ●

| ●

|

● |

| Ƙarfi wadata | Danna maɓallin gwaji na kariyar da'ira don tabbatar da yana iya aiki akai-akai Sauya kebul ɗin idan ya karye | ●

● |

|

● |

|

“●”………… lokacin kulawa

9.3 Binciken rashin aiki akai-akai da mafita

Yayin amfani, naúrar ruwa da na'urorin lantarki na iya bayyana wasu matsaloli. An jera rashin aiki akai-akai kamar haka:

Da fatan za a yi amfani da kayan aikin da aka haɗe, kayan gyara ko wasu kayan aikin tare da takardar shaidar aminci yayin kulawa ko maye gurbin sassa. An hana amfani da kayan aiki da kayan gyara ba tare da takardar shaidar aminci ba.

| Rashin aiki na na'ura mai aiki da karfin ruwa | |||

| No | rashin aiki | rashin aikin yi nazari | Magani |

| 1 | Motar famfo baya aiki |

| |

| 2 | Motar famfo tana jujjuyawa a hankali tare da ƙarar rashin daidaituwa |

| 1. Tabbatar cewa nauyin motar ya kasance ƙasa da 3 MPa 2. Gyara ko maye gurbin famfo 3. Tsaftace tace 4. Duba rashin kwanciyar hankali na iko |

| 3 | Silinda yana aiki mara kyau |

| |

| 4 | Silinda ya zube | 1. Zoben mai laifi ne 2. Silinda ko fistan sun lalace sosai | 1. Sauya zoben mai 2. Sauya silinda |

| 5 | Ba za a iya ƙara matsa lamba ba ko jujjuyawar ta yi girma da yawa | 1. An toshe ainihin bawul ɗin ambaliya. 2. Famfu ya zube. 3. An sassauta raƙuman haɗin gwiwa na famfo ko maɓalli na maɓalli ya tsallake. 4. Ba a kulle bawul ɗin taimako na matsa lamba | 1. Tsaftace ko maye gurbin ainihin bawul ɗin da ke kwarara 2. Sauya famfo 3. Sauya raunin haɗin gwiwa 4. Kulle bawul |

|

Rashin aikin na'urorin lantarki | |||

| 1 | Injin baya aiki |

| 1. Duba wutar lantarki 2. Duba ikon aiki 3. Bude mai katse laifin kasa |

| 2 | Canza tafiye-tafiye na kuskuren ƙasa |

| 1. Duba igiyoyin wutar lantarki 2. Duba abubuwan lantarki. 3. Bincika na'urar amincin wutar lantarki mafi girma |

| 3 | Zazzabi mara kyau yana ƙaruwa | 1. Mai sarrafa zafin jiki yana buɗewa 2. Na'urar firikwensin (pt100) ba ta da kyau. Ƙimar juriya na 4 da 5 na soket ɗin farantin dumama ya kamata ya kasance cikin 100 ~ 183Ω 3. The dumama sanda a cikin dumama farantin ne na al'ada. Matsalolin da ke tsakanin 2 da 3 yakamata su kasance cikin 23Ω. Juriya tsakanin shugaban sandar dumama da harsashi na waje dole ne ya wuce 1MΩ 4. Idan karatun mai kula da zafin jiki ya kasance fiye da 300 ℃, wanda ke nuna cewa yana iya lalacewa ko haɗin haɗin. Idan mai kula da zafin jiki ya nuna LL, wanda ke nuna firikwensin yana da gajeriyar kewayawa. Idan mai kula da zafin jiki ya nuna HH, wanda ke nuna kewayawar firikwensin a buɗe yake. 5. Gyara zafin jiki ta maballin dake kan mai sarrafa zafin jiki.

| 1. Duba haɗin lambobin sadarwa 2. Sauya firikwensin

3. Sauya farantin dumama

4. Sauya mai kula da zafin jiki

5. Koma zuwa hanyoyin don saita zafin jiki 6. Duba kuma maye gurbin masu tuntuɓar idan ya cancanta |

| 4 | Rashin iko lokacin dumama | Hasken ja yana haskakawa, amma har yanzu zafin jiki yana ƙaruwa, wato saboda haɗin haɗin yana da kuskure ko haɗin gwiwa 7 da 8 ba zai iya buɗewa lokacin da ake buƙatar zafin jiki ba. | Sauya mai sarrafa zafin jiki

|

| 5 | Kayan aikin tsarawa baya juyawa | Maɓallin ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun kayan aikin an yanke su. | Sauya ƙayyadadden ƙayyadaddun kayan aikin tsarawa ko ƙaramar sprocket |