SDC315 Band ya ga Aikin Manual

Bayani na Musamman

Kafin sarrafa na'ura, kowa dole ne ya karanta wannan bayanin a hankali kuma ya kiyaye shi da kyau don tabbatar da amincin kayan aiki da ma'aikacin, da kuma lafiyar wasu.

2.1 Ana amfani da wannan na'ura don yanke bututu da aka yi daga PE, PP da PVDF kuma ba za a iya amfani da su don yanke kayan da ba a bayyana ba; in ba haka ba injin na iya lalacewa ko ya haifar da hatsari.

2.2 Kada a yi amfani da injin a wurin da ke da haɗarin fashewa

2.3 Dole ne a sarrafa na'ura ta hanyar ƙwararrun ma'aikata, ƙwararrun ma'aikata da horarwa.

2.4Ya kamata a yi amfani da injin akan busasshen wuri. Ya kamata a ɗauki matakan kariya lokacin da ake amfani da shi a cikin ruwan sama ko a ƙasa mai jika.

2.5 Ƙarfin shigarwa yana cikin 380V± 10%, 50 Hz. Idan aka yi amfani da tsawaita layin shigarwa, layin dole ne ya sami isasshen sashin jagora.

2.6 Cika man fetur na ruwa (N46 ISO3448) a cikin tanki kafin lokacin farko na amfani. Girman mai yakamata ya zama kusan 2/3 na tanki.

Tsaro

Alamomi masu zuwa sunean sakaga mashin.

3.2. Kariya don Tsaro

Lokacin aiki da injin, umarni da ƙa'idodin aminci yakamata a kiyaye su a hankali.

3.2.1 Ya kamata ma'aikaci ya kasance horarwa da ƙwararrun ma'aikata.

3.2.2 Cikakken dubawa da kula da injin a kowace shekara don aminci da amincin injin.

3.2.3 Power: Akwatin rarraba wutar lantarki yakamata ya kasance yana da mai katsewa ƙasa tare da ma'aunin amincin wutar lantarki mai dacewa.

Ƙasa: Duk rukunin yanar gizon yakamata ya raba waya ta ƙasa iri ɗaya kuma tsarin haɗin ƙasa yakamata a gama da gwadawa ta hanyar kwararru.

3.2.4 Adana na'ura:

Don hatsarori, duk kayan aikin dole ne a yi amfani da su kamar haka:

※ Kar a taɓa sassan electrophorus

※ Hana cire kebul don cire haɗin

※ Kar a sanya abu mai nauyi ko kaifi akan igiyoyin, kuma sarrafa zafin kebul a cikin iyakacin zafin jiki (70℃)

※ Kada ku yi aiki a cikin yanayin jika. Bincika idan tsagi da takalma sun bushe.

※ Kar a fantsama injin

3.2.5 Duba yanayin rufin injin lokaci-lokaci

※ Duba insulation na igiyoyi musamman maki extruded

※ Kar a yi aiki da injin a cikin matsanancin yanayi.

※ Bincika idan mai katsewar kasa yana aiki da kyau aƙalla kowane wata.

※ Duba ƙasa na injin ta ƙwararrun ma'aikata

3.2.6 Tsaftace injin a hankali

※Kada a yi amfani da kayan da ke lalata rufin cikin sauƙi (kamar gas, abrasive, da sauran kaushi)

※Ya kamata a cire haɗin wutar lantarki lokacin kammala aikin.

Idan kawai bin abin da aka ambata a sama, yin taka tsantsan zai iya aiki da kyau.

3.2.7TSAYAWAR GAGGAWA

Duk wani hali na bazata yana faruwa, da fatan za a danna "TSAYAR GAWAR GAWA" nan take don tsayar da injin. Bayan warware matsalolin juya TSAYAWAR GAGGAWA a kusa da agogo don sake fara na'ura.

3.2.8 Tsantsan sassa:Bincika idan an gyara bututun daidai da tam. Tabbatar cewa ba zai iya zamewa zuwa ga ma'aikacin rauni ba

3.2.9 Ma'aikataaminci yayin aiki

Cire kayan ado da zobe, kuma kada a sanya suturar da ba ta dace ba, guje wa sanya yadin takalmi, dogon gashin baki ko dogon gashi wanda za a iya sawa cikin injin.

3.2.10Tsaftace wurin da tsabtay

Jama'a, ƙazanta da ƙaƙƙarfan wuri ba su dace da aiki ba, don haka yana da mahimmanci a tsaftace wurin da tsabta.

3.2.11 Ba za a taɓa barin wanda ba shi da horo ya yi aiki da injin kowane lokaci.

3.3 Hatsari Mai Hatsari

3.3.1 Band saw

Kwararren mutum ne kawai ko ƙwararrun ma'aikata ke sarrafa wannan na'ura, in ba haka ba haɗarin da ba'a so zai iya haifar da shi.

3.3.2 Saw Ruwa

Kada a taɓa igiyar gani mai gudu, ko rauni na iya haifarwa

3.3.3 Yankewa

Kafin yanke, tsaftace yashi a waje da bututu ko wasu daftarin da aka yi a cikin bututun lokacin jigilar kaya. Wannan zai iya guje wa lalacewar da ba a so ba na igiyar zarto ko wasu hatsarori

Matsakaicin Range da Sigar Fasaha

| Nau'in | SDC - 315 |

| Kayayyakin yankan | PE, PP, PVDF |

| Max. Yanke iya aiki | mm 315 |

| Yanke kwana | 0°~67.5° |

| Rashin daidaito na kusurwa | ≤1° |

| Layin saurin tsinke | 230m/min |

| Yanayin yanayi | - 5 ℃ 45 ℃ |

| Tushen wutan lantarki | 380 V± 10% |

| Yawanci | 50 Hz |

| Jimlar halin yanzu | 5A |

| Jimlar iko | 3.7 kW |

| Motar Tuƙi | 2.2 KW |

| Injin na'ura mai aiki da karfin ruwa | 1.5 KW |

| Juriya na rufi | >1MΩ |

| Max. na'ura mai aiki da karfin ruwa matsa lamba | 6 MPa |

| Jimlar nauyi (kg) | 1100 |

Bayani

A band saw za a iya amfani da yanke PE bututu bisa ga kafa kwana a lokacin da yin gwiwar hannu, Tee da giciye, sabõda haka, inji yana da fasali na high aiki yadda ya dace da kuma amfani kudi na kayan.

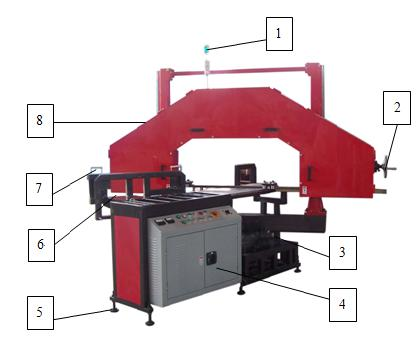

5.1 Bayanin sassan

| 1. na'urar gargadi | 2. Tashin hankali | 3. ma'aunin kwana | 4. akwatin sarrafawa |

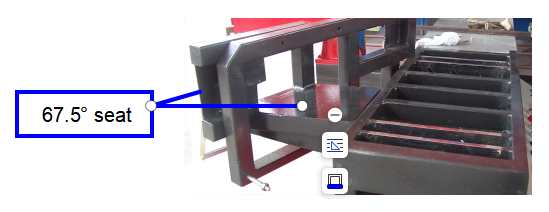

| 5. matakin daidaitawa | 6. 67.5° wurin zama | 7. gyara na'urar | 8.akwatin sawaye |

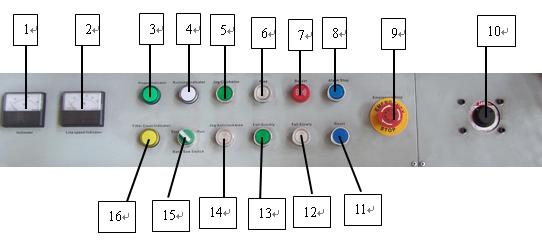

5.2 Aiki panel

| 1. Voltmeter | 2. Alamar Gudun Layi | 3. ikon nuna alama | 4. Mai nuna gudu |

| 5. Yin tafiya ta agogo baya | 6. Tashi | 7. Buzzer | 8. Tsayar da ƙararrawa |

| 9. Tasha gaggawa | 10.Feed gudun daidaitawa | 11. Sake saiti | 12. Faduwa a hankali |

| 13. Faduwa da sauri | 14. jog anti agogon hannu | 15. Band saw canza | 16. man famfo aiki nuna alama |

Shigarwa

6.1 Dagawa da shigarwa

6.1.1 Idan an yi amfani da cokali mai yatsu yayin shigarwa, saka cokali mai yatsa a hankali daga kasan na'ura don guje wa lalata bututun mai ko kewaye.

6.1.2 Lokacin sanya na'ura, injin ya kamata a kiyaye shi da kwanciyar hankali da matakin ta hanyar daidaita madaidaicin matakin

6.1.3 Wannan ma'auni na'ura na iya yanke kwana 0 ~ 67.5 °, idan an buƙata kwana a cikin 45 °, ya kamata a cire wurin zama na 67.5 ° kafin aiki.

Aiki

7.1 Farawa

7.1.1 Ƙaddamar da injin, kuma alamar wutar lantarki dole ne a kunne (idan ba a kunne ba, haɗin ba daidai ba ne).

7.2 Gwajin akwatin gani yana motsawa sama da ƙasa ta hanyar jujjuya madaidaicin saurin ciyarwa akan sashin dama na aiki.

7.3 Danna maballin "jog a kusa da agogo" da "jog a gaban agogon agogo" don duba hanyar gudu na igiyar gani. Idan yana juyawa ta hanyar da ba daidai ba, musayar haɗi tsakanin kowane wayoyi masu rai guda biyu masu alaƙa da wutar lantarki.

7.4Yanke aiki

7.4.1 Sauke dunƙule makullin kwana, tura akwatin gani da hannaye zuwa kusurwar da ake buƙata (kamar yadda kusurwar da ake buƙata), kuma ɗaure dunƙule makullin kwana.

7.4.2 Ɗaga akwatin tsintsiya mai tsayi zuwa tsayi (wanda aka ƙayyade ta diamita na bututu da za a yanke) don tabbatar da haƙoran haƙori yana sama da bututu.

7.4.3 Sanya bututun yankan akan teburin aikin, daidaita matsayin yanke, kuma gyara bututu tare da bel na nylon ta hanyar kulle na'urar.

7.4.4 Fara tsinken gani, lokacin da igiyar gani ta sami ƙayyadaddun gudu (Alamar Gudun zai haskaka), kunna madaidaicin saurin ciyarwa don faɗi akwatin gani a hankali. Ya kamata a daidaita saurin fadowa bisa ga diamita na bututu da kauri.

7.4.5 Lokacin da za a gama yankan, da fatan za a riƙe bututun da aka yanke don guje wa toshe ruwan zato.

7.4.6 Latsa maɓallin gaggawa idan wani rashin lafiya ya faru yayin yanke. Bayan warware matsalolin juya TSAYAWAR GAGGAWA a kusa da agogo don sake fara na'ura.

7.4.7 Saw ruwa zai tsaya kai tsaye lokacin da ya kai ƙananan matsayi

7.4. 8 Lokacin da aka gama yanke Cire bututun da aka yanke kuma sake yanke.

7.4. 9 Wannan misali inji iya yanke kwana 0 ~ 67.5 °, idan wani kwana a cikin 45 ° ake bukata, da 67.5 ° wurin zama ya kamata a cire kafin aiki a kan bututu, nuna kamar haka:

Tsanaki:

1) sake kunna injin a cikin mintuna 30 bayan yanke wutar don kare mai canzawa.

2) Duk injin dole ne ya zama ƙasa don tabbatar da aminci

3) Dubawa da kiyaye kayan aikin lantarki dole ne ƙwararren mutum ya yi

Laifi da Magani

Da fatan za a yi amfani da kayan aikin da aka haɗe, kayan gyara ko wasu kayan aikin tare da takardar shaidar aminci yayin kulawa ko maye gurbin sassa. An hana amfani da kayan aiki da kayan gyara ba tare da takardar shaidar aminci ba.

Table.1 Rashin aikin injiniya

| Abu | Bayani | Bincike | Magani |

| 1 | Band saw ruwa an cuci | 1. Ba'a kulle kusurwar wurin zama na juyawa sosai. 2. Band saw ruwa ba a tensioned tam. 3. Wurin zato yana gudu da sauri a hankali ko kuma tsinken ganimar ta faɗi da sauri | 1. Daure na'urar kulle kusurwa. 2. Daidaita abin nadi zuwa tashin hankali band saw ruwa. 3. Rage saukar da faɗuwar gudu da daidaita high layin gudu na saw ruwa. |

| 2 | Band saw ruwa sauke | 1. Ba a daidaita masu riƙon gani da kyau ba. 2. Band saw ruwa ba tensioned. 3. Saw ruwa dabaran an sassauta. 4. An toshe ainihin bawul ɗin ambaliya | 1. Daidaita mariƙin gani don gyara band saw ruwa a wuri mafi kyau. 2. Daidaita abin nadi zuwa tashin hankali band saw ruwa. 3. Daure dabaran tsintsiya madaurinki daya. 4. tsaftace ainihin bawul ɗin ambaliya |

Table.2 Laifin tsarin na'ura mai aiki da karfin ruwa

| Abu | Bayani | Dalilai | Magani |

| 1 | Motar famfon mai baya aiki | 1. Contactor ba a rufe 2. Layukan ciki sun katse 3. Motar kuskure ne. | 1. Duba mai tuntuɓar; 2. Duba haɗi ko toshe. 3. Dubawa da gyara motar. |

| 2 | Babu matsa lamba a cikin tsarin, da ƙarar ƙara a cikin famfo | 1. Hanyar juyawa na motar famfo mai ba daidai ba ne; 2. An katse haɗin ma'amala na mota da famfo mai 3. Man bai isa ba ko datti sosai. | 1. Ya kamata ya rika juya agogo baya; 2. Duba ma'aurata; 3. Cika ko canza mai; |

| 3 | Gudun ɗagawa na babban silinda yana da sauri ko kuma a hankali | 1. Tsarin tsarin yana da yawa ko ƙananan; 2. An daidaita bawul ɗin maƙura ba daidai ba; 3. An daidaita bawul ɗin kunci mai sarrafawa ba daidai ba. | 1. Daidaita tsarin tsarin; 2. Daidaita bawul ɗin maƙura; 3. Daidaita bawul shugabanci guda ɗaya. |

| 4 | Ba za a iya daidaita matsa lamba zuwa sama ba ko jujjuyawar matsa lamba ya yi girma da yawa | 1. An toshe ƙwanƙwasa bawul ɗin da ke kwarara 2. An toshe tace mai. 3. An toshe ƙwanƙwalwar bawul ɗin da ke kwarara | 1. Cire haɗin & wanke ko canza bawul ɗin ambaliya 2. A wanke tace mai. 3 .Disassemble da tsaftace ambaliya core. |

Zane-zane na Wuta & Na'ura mai aiki da karfin ruwa

9.1 Jadawalin naúrar da'ira (Yin magana akan kari)

9.2 Zane na na'ura na'ura mai aiki da karfin ruwa (Nazarin shafi)